EPCwin - the software for professional punches

The creation of embroidery pattern data for the various embroidery processes is still one of the biggest challenges for professional embroidery. Here, the unique, modularly designed software EPCwin sets whole new standards in terms of functionality and ease of use.

Whether for badges, logos, applications, designs for haute couture, tablecloths, curtains, allover and etching embroidery - EPCwin has all the program levels from designing to drawing and puncturing to editing. As a user, you are always optimally managed and supported in all work steps. That means: fast and efficient work.

EPCwin handles all popular image formats from various sources such as scanners, internet, clipart. Effective functions are available for editing these templates. Thus, for example, scanned partial images can be joined together to a complete original. Specially developed functions for the drawing technique allow the targeted creation of contours, regardless of the quality of the image templates. Alternatively, vector files in the formats dxf, wmf, emf and ai can be imported from other drawing programs. Drawing the exact contours of a pattern is the basis for a high-quality embroidery design.

The most important functions at a glance:

- Freedom curves

- Parallels to fre-form curves

- Geometric figures

- Random orientation

- Free editing of all line bases

- Simple selection of objects by avoiding

- Change selected objects by turning, compressing, stretching, copying, moving graphically or numerically

- Own administration for saving and loading character elements

- Acquisition of True Type fonts as contours for monograms

- Helper functions such as grids, guides, comment texts

- Automatic rapport also with head and needle selection

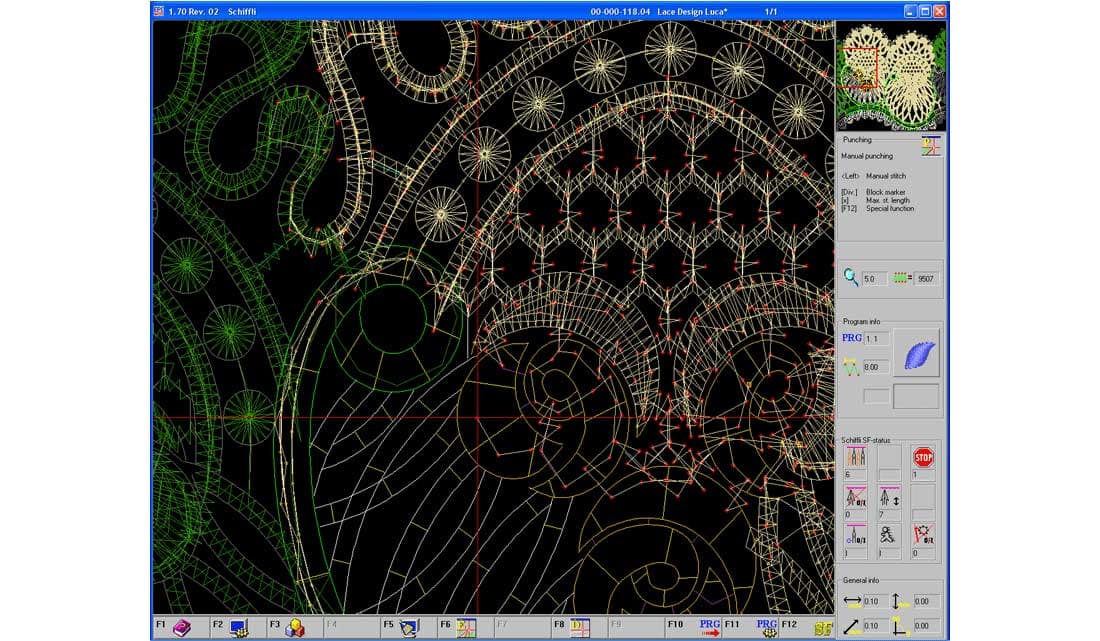

Schiffli Design

In addition to multi-head embroidery, EPCwin also supports Schiffli embroidery. EPCwin offers Schiffli design for professional users. A large number of automatic programs for drawing, drilling and etching causes an enormous saving in drawing time.

Punching

There are various methods available for the rational generation of stitch data.

Punching

Punching on the screen: The procedure is particularly recommended, if the template has embroidery-technically usable forms. The contours are created when using automatic punch programs. This saves a lot of time.

The transfer of existing drawing lines: Existing drawing lines which are imported by EPCwin or other drawing programs can be selectively selected when punching. By shortening, extending, connecting and supplementing these lines with the takeover, the user has every freedom.

The combination of both methods: In difficult sample passages you use the drawing functions with subsequent adoption of these lines. This simplifies and accelerates your work process,

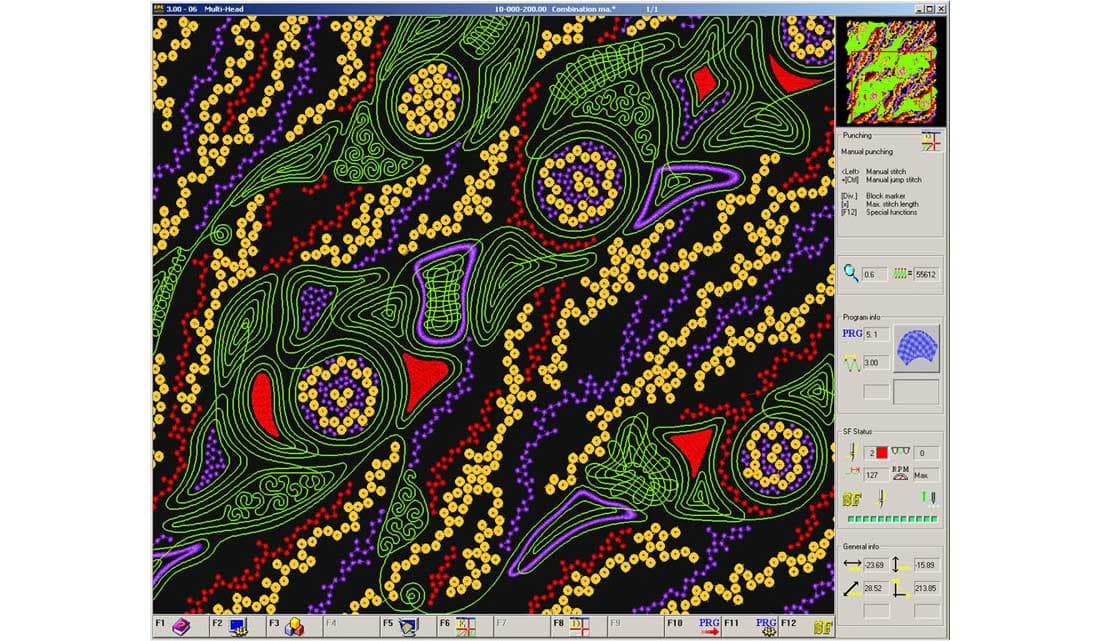

Punch with EPCwin

Schiffli punch with EPCwin

Special functions for multi-head and Schiffli machines

EPCwin supports all common special functions such as color change, thread cut, sequin, head switch - for multi-head embroidery machines as well as single needle switching, repeat & color change, drilling etc. and for Schiffli embroidery machines. Especially for complex patterns with head and single needle switching, EPCwin impresses with its optimal graphic color representation.

Excellent automatic programs for creativity

With EPCwin you have an unrivaled and enormous range of automatic embroidery programs. By autorouting, the program independently chooses the most effective path between the beginning and the end of an object. The quality can be controlled at any time via precise embroidery-technical parameters.

- Automatic stitch density adjustment based on the stitch length

- Exactly adjustable train compensation

- Stitch shortening at corners and tight curves

- Short-long rule to avoid thread breakage

- Various corner variants in all satin stitch programs

- Exact, automatic underlay in many variants

- Free start and end point

Edit

- Correct and adjust contours and stitches

- Changing the embroidery process with the help of the film function

- Changing and exchanging program parameter sets

- Cut, insert and manage sample parts

- Rotate, mirror, zoom in, zoom out, distort pattern parts with optimal stitch density adjustment

Input and output of data

Stitch data is input and output in all common machine codes.

- For Schiffli embroidery machines: Lässer, Saurer, Hiraoka, ZSK

- For multi-head embroidery machines: ZSK, Tajima, Barudan, Melco, etc.

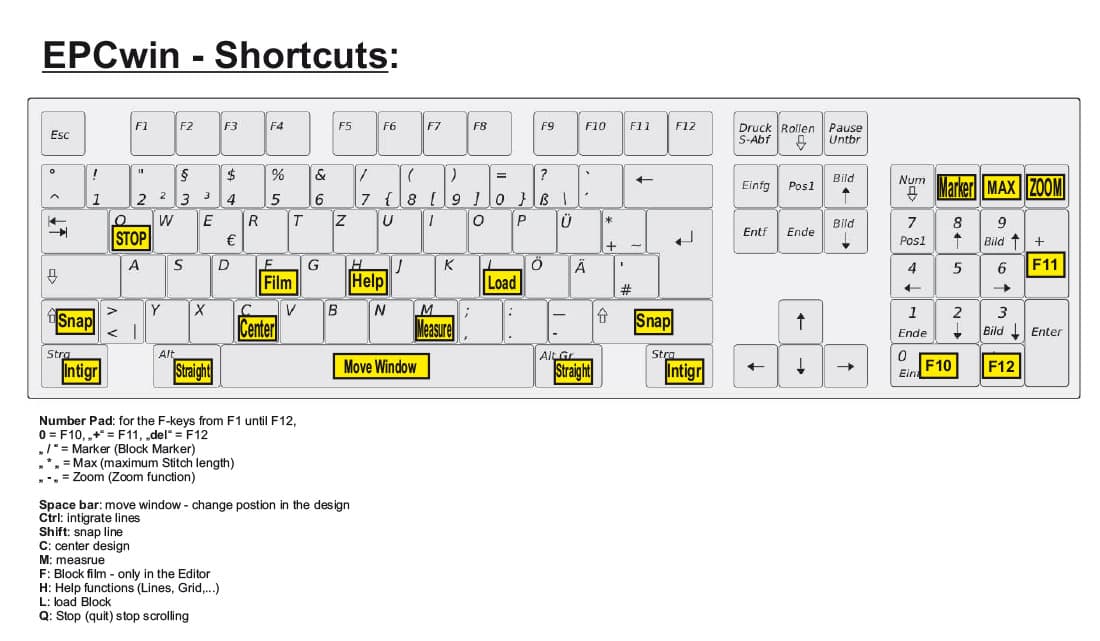

Shortcuts