ZSK SPRINT 7L

SPRINT - We set new standards

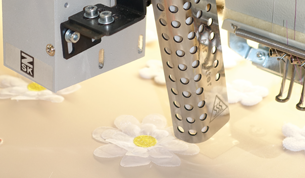

The series is equipped with the thinnest tubular arm of the embroidery industry. It enables orders that could not previously be processed, eg shirt pockets or shoes. The machines embroider without "picker" on the front. Your advantage: textiles can no longer get caught in the hook and thus remain undamaged. Rely on quality production with the smallest clearances on the tubular arm.

MADE IN GERMANY

MADE IN GERMANY

ZSK SPRINT 7L

Various application and expansion options for all requirements and areas.

The SPRINT Series includes all features of an industrial embroidery machine that makes it the most advanced compact embroidery machine in the market.

The SPRINT was the first machine at ZSK to be equipped with the slimmest tubular arm in the industry. Due to this feature, the machine is capable to embroider shirt and trousers pockets. The slim tubular arm sets the benchmark for the industry.

Operation without a picker avoids textiles being damaged from the picker pulling fabric into the hook.

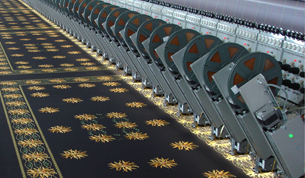

The machine is available for tubular, cap and border frame embroidery with a maximum speed of 1200 stitches per minute. The strength of the industrial design and the precision of the components used allow the SPRINT to be your ideal solution for embroidery on shoes, leather products or even car mats.

Being equipped with the T8-2 controller, the SPRINT Series is ideal for workflow solutions.

With the embroidery machines of the SPRINT series, in addition to the best embroidery quality, we offer many additional devices and frames that support you in the development and implementation of your creative ideas and make the requests of your customers an economic success for you.

Main features

- Single head

- 18 needles/colours

- Embroidery speed 1,200 stitches/min.

- Embroidery width up to 600mm

- Automatic thread cutter

- Smallest tubular arm of industrial embroidery

- Upper and lower thread guard

- Automatic reverse embroidery function

- Height-adjustable fabric presser

- Contouring with lowered needle

- Low noise and low weight

- T8-2 control unit

- Integrated design editor

- Accepts all common industrial embroidery codes

- Storage for approx. 80 million stitches

- Automatic fault analysis

- Windows based networking

- Built and designed for 24/7 production

- High value retention

- Made in Germany

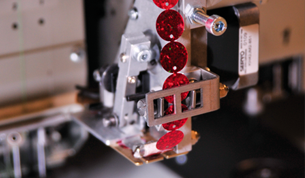

T8-2 Control terminal

- Intuitive and logical user guidance

- Ready for networking

- Accepts all common industrial embroidery codes

- Can be operated in 14 languages

- Storage for up to 80 million stitches

- Barcode capability

Our ZSK embroidery machines provide endless possibilities

|

Flat embroideryFlat embroidery with border frame meets the highest demands in all application areas. Flat stitch offers almost endless possibilities to optimally present your motif. |

CapThe cap extension allows you to efficiently implement your ideas in the capstick area and thus the production of individual caps in small series. |

ShoesEmbroidering a sports shoe with its name, the name of your favourite team or your favourite player makes it a unique and very personal object. |

Name BadgesWith the help of the stencil template frame, name badges can be created efficiently, through simple handling and with little effort with different or even the same names. |

|

Shirt PocketsThe embroidery of shirt pockets with personal initials, a company logo or fashionable application individualizes the garment and is an expression of personality or corporate identity. |

TubularEmbroider on most standard garments and textiles with the Premium Allied Grid-Lock plastic tubular frames, available in various sizes.

|

HoopMaster MagneticHoopMaster Magnetic frames use strong magnets to clamp over difficult items such as seams, zippers, velcro and more. No need to worry about clamping anymore. |

CylinderUse the cylinder frame especially for embroidering around closed parts, such as jacket sleeves, socks, gloves, bracelets etc., and to process names, logos or fashionable applications. |

|

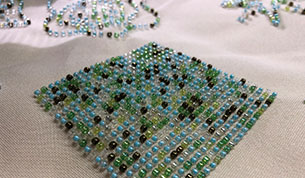

SequinsWith unique precision and an outstanding 1,000 stitches per minute you not only embroider sequins in different sizes, but also rhinestones to the most beautiful designs. |

Beads/pearlsWith this latest development, you can now also expand the possibilities with pearl embroidery and increase the appearance of your designs even more. |

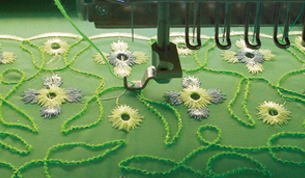

CordingVary not only with colors, but also with cords in different strengths and structures. Give your patterns an exciting look and feel. |

BoringUsing a knife, a small hole is automatically cut, which allows the needle and thread to be enlarged and repackaged, thus increasing the value of your designs. |

Our ZSK embroidery machines can be adapted with additional attachments

Technical Data - Machine |

||

| Heads | 1 | |

| Needles | 18 | |

| Pantograph Travel max. [mm] | 600 | |

| Max. Stitches Tubular / Flat [mm] | 1200 | |

| Max. Stitches Cap [mm] | 1000 | |

| Width [mm] | 1410 | |

| Depth [mm] | 1220 | |

| Height [mm] | 1640 | |

| Power Supply [V] | 230 | |

| Connected Load [Watt] | 220 | |

| Net Mass [Kg] | - |

Technical Data - Embroidery Field |

||

| Width [mm] | 600 | |

| Depth [mm] | 400 | |

| Border Frame max. [mm] | 600 x 400 | |

| Tubular max. [mm] | - | |

| Cap 360 max. [mm] | 360 x 70 | |

| Shoes max [mm] | 124 x 175 |

What do you get from us?

We are the sole UK supplier for ZSK industrial embroidery machinery and equipment, therefore we really know our stuff with these machines. All of our technicians are fully trained at ZSK headquarters in Germany, by the developers themselves.

We offer unbeatable start-up packages for every customer, with every machine. Our wealth of knowledge, gathered over more than 45 years in the industry, provides each customer with the essential information they require to become successful on their embroidery venture.

If you are unsure of which machine is right for you, our friendly sales team are on hand to discuss your requirements, and offer the perfect machine to fulfil your needs. We will never intentionally sell you a machine that is not suitable for your requirements.

Free delivery, installation and training

We offer free delivery, installation and training on all of our machines. Our qualified technicians will aim to arrive with you in the morning with your new machine, install the machine in your desired location, and complete a full training course with up to a recommended amount of four persons.

Our technicians provide hands-on-training, which we believe is the most successful method of training, in the full operations of the machine, general maintenance of the machine and anything else you need to know to get you up and running. Our technicians will never leave you without your full confidence in running the machine, whether this happens after two hours or eight hours.

Nationwide

We offer our services nationwide at no extra charge! Our head office is based in Leeds, West Yorkshire. We also have a technician in Paisley, Scotland, and another technician based in London.

As we are spread across the UK Mainland, we guarantee that we will be able to get to you quicker than other competitors, no matter where you are based.

Warranty and support

All of our ZSK machines come with a 24 month on-site warranty. We are sure you won't need us in this time, however in case you do, our technicians will get to you as quickly as possible to get you back up and running. We offer telephone support with our technicians, who will always aim to get any problems fixed over the phone in the first instance, to prevent any unnecessary down time in your production.

Payment and trading in

We offer flexible business leasing finance packages, tailored to suit you, over two, three, four or five years, whether you are a new start business or an established business for over three years.

See our finance calculator tab to work out what this machine would cost you.

We also offer guaranteed buy-back and part exchange on all machines bought from us. If you find that your original machine is no longer fulfilling your production requirements, we will happily take the machine as part exchange against another machine.